Intambo yocingo lwentsimbi ukufumanisa Intambo yocingo yenye yezona ndawo zibalulekileyo ze-crane, kwaye ukhuseleko lwayo luchaphazela ngokuthe ngqo umsebenzi we-crane yonke.Ngoko ke, kumsebenzi wemihla ngemihla, kufuneka senze umsebenzi omhle ekuhloleni iintambo zocingo, ukuphelisa iingozi ezifihliweyo ngexesha, kwaye uqinisekise ukhuseleko.

1. Ukuhlolwa kwembonakalo:

1)Jonga inkangeleko yeentanda, i-deformation kunye ne-corrosion;

2)Jonga ukuba umphezulu ugudile kwaye ulungelelene;

3)Jonga inani kunye nobude beengcingo eziqhekekileyo (ngokuqhelekileyo zingaphantsi kwe-2 ngemitha).

2. Uvavanyo lokuqina:

Uvavanyo lwe-tensile kukutsala isampuli kunye nobude be-10mm ukuya kumgama we-100 ~ 150mm ukusuka ekupheleni kovavanyo, kwaye emva koko utsale isampuli kwindawo yokuqala ukusuka kumgama we-50mm ukusuka ekupheleni kovavanyo kwisantya esithile esiqhubekayo.

La manqaku alandelayo kufuneka anikwe ingqwalasela ngexesha lovavanyo lwe-tensile:

1) Ngaphambi kokulinganisa amandla, ikhebula lensimbi eliza kuhlolwa kufuneka likhululeke malunga nemizuzu emi-5 kwaye ukungcola okufana neoli kunye nothuli kufuneka kususwe;

2)Xa ulinganisa amandla, amandla kufuneka afakwe kancinci kude kube yixabiso elichaziweyo;

3)Emva komlinganiselo ngamnye, umshicileli kufuneka abuyiselwe kuqanda phambi komlinganiselo wesibini;

4) Ukuba kuyimfuneko ukulinganisa iziphumo ezininzi, eyona inkulu iya kuphumelela.

3. Jonga inani leengcingo ezaphukileyo:

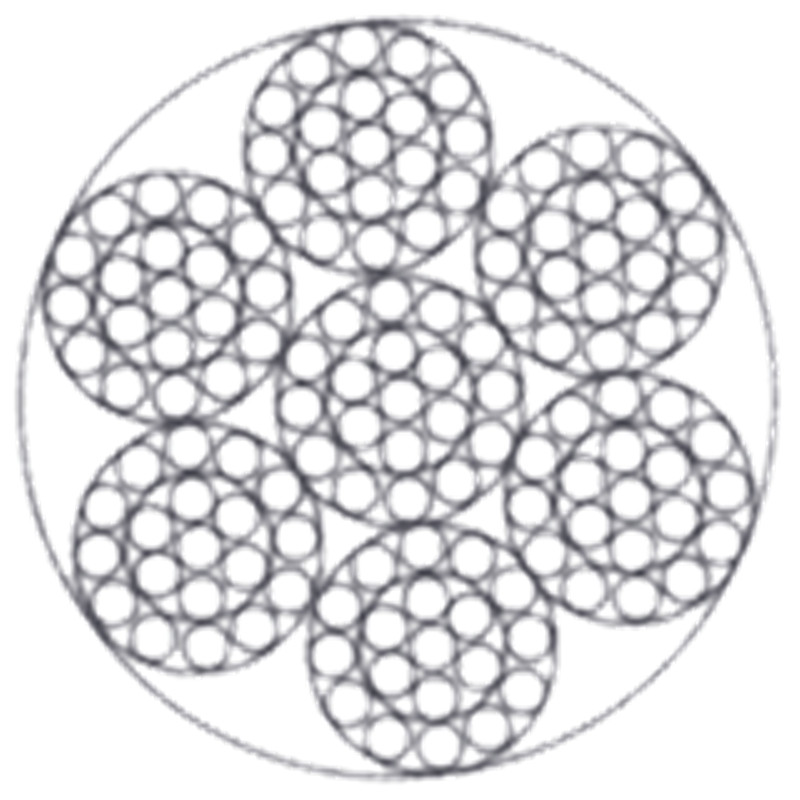

Inani leentambo ezaphukileyo libhekiselele kwipesenti (%) yeentsinga ezinobubanzi obungaphantsi okanye obulingana nedayamitha yesiqhelo, ebonisa inani lokubandakanywa okungeyontsimbi kulwakhiwo lwangaphakathiintambo yocingokunye nenqanaba lokunxiba.

4. Ukuhlola ubomi bokudinwa:

Emva kokuba inani elithile leediski zecandelo eliqhelekileyo zifakwe kwi-jig kwaye zilungisiwe, ukugoba idiskhi nganye kwidiskhi yecandelo eliqhelekileyo ngokuphindaphindiweyo ngokwenani elichaziweyo lamaxesha kunye namaxesha athile, kwaye emva koko ususe iibholiti zokudibanisa zecandelo ngalinye eliqhelekileyo. kwaye uzidibanise.Zifake kwiikomityi zokulinganisa ezikhethekileyo eziphawulwe ngezikali (iikomityi zokumejarisha zichazwe njengeentambo zentsimbi eziza kulinganiswa), uze ubeke ezi komityi zokulinganisa kwindawo enobushushu obuyi-20±1°C ngaphezu kweeyure ezi-3. ukubala isethi yamaqhina.Ukudinwa ixabiso lobomi bediski.

5. Ukuhlolwa kokutya:

Yindlela elula yokuvavanya umgangatho womaleko owenziwe yizinki ngendlela yokuntywiliselwa kweasidi.Ubukhulu bomaleko owenziwe ngegalvanized afakwe kwisisombululo se-sulfuric acid ngokubanzi phakathi kwe-0.15 kunye ne-0.2 mm.Kubonisa ukuba le nkqubo yokugaya ayifanelekanga okanye inqumle iikona.

6. Uvavanyo lokujija:

Ekusetyenzisweni, kufunyenwe ukuba abanye abasebenzisi baya kusebenzisa ezinye izinto eziphantsi ukuze bathathe indawo yentsimbi ephezulu yokuvelisa iigwegwe okanye izilingi ukwenzela ukugcina iindleko.Oku akuyi kuchaphazela kuphela ubomi benkonzo yemveliso, kodwa kubangele iingozi ezinkulu zokhuseleko.Ke thina Xa sithenga, kufuneka sikhethe iimveliso ezikumgangatho ophezulu zemveliso rhoqo ukuze siqinisekise ukhuseleko lobuqu kunye nepropathi yethu!

Ixesha lokuposa: Jul-22-2022