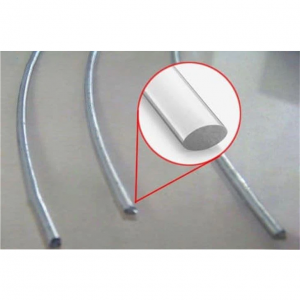

I-Hot Dip Zinc Alloy Wire

Zinc ialloy wireyimathiriyeli edumileyo esetyenziswa kumashishini ahlukeneyo ngenxa yeempawu zayo ezizodwa kunye nokuguquguquka.Iqulunqwe ngumxube we-zinc kunye nezinye isinyithi, ezifana nobhedu, i-aluminiyam, okanye i-magnesium, eyandisa amandla kunye nokuqina kwayo.I-alloy isoloko isetyenziselwa iinkqubo zokuvelisa, ukwakhiwa, kunye nokwenza izacholo.

Enye yezona zinto zibalulekileyo zocingo lwe-zinc alloy kukungasebenzi kakuhle.Le propati yenza kube lula ukubumba kunye nokugoba kwiifom ezahlukeneyo ngaphandle kokuphuka okanye ukuqhekeka.Lo mgangatho ukwavumela ukuyilwa koyilo oluntsonkothileyo, okwenza kube lukhetho oludumileyo kubenzi bezacholo.I-alloy inokubunjwa ngokulula kwiimilo ezahlukeneyo, ezifana ne-loops, i-spirals, kunye neepateni ezintsonkothileyo, nto leyo eyenza ibe yintandokazi phakathi kwabayili.

IiNgcaciso zokuSebenza ngocingo olwenziwayo

Njengoko ucingo lwegalvanized luhlelwa ngokobuninzi be-zinc coating, le theyibhile ilandelayo ichaza umahluko phakathi kocingo oluqhelekileyo, olunzima kunye noluphezulu oluphezulu.

| Idayamitha yeNominal | Ubuncinane boMatyatho oMatye (g/m2) | ||

| Galv esemgangathweni. | Heavy Galv. | Extra-highGalv. | |

| ngaphezulu kwe-1.80mm ukuya kuthi ga kunye nokubandakanya.2.24mm | 35 | 215 | 485 |

| ngaphezulu kwe-2.24mm ukuya kuthi ga kunye nokubandakanya.2.72mm | 40 | 230 | 490 |

| ngaphezulu kwe-2.72mm ukuya kuthi ga kunye nokubandakanya.3.15mm | 45 | 240 | 500 |

| ngaphezulu kwe-3.15mm ukuya kuthi ga kunye nokubandakanya.3.55mm | 50 | 250 | 520 |

| ngaphezulu kwe-3.55mm ukuya kuthi ga kunye nokubandakanya.4.25mm | 60 | 260 | 530 |

| ngaphezulu kwe-4.25mm ukuya kuthi ga kunye nokubandakanya.5.00mm | 70 | 275 | 550 |

| ngaphezulu kwe-5.00mm ukuya kuthi ga kunye nokubandakanya.8.00mm | 80 | 290 | 590 |

IiPropati zoMdayamitha

Umgangathoucingo oluGalisiweyoyenzelwe ukuthobela oku kunyamezelwa kwedayamitha ilandelayo:

| I-Nominal Wire Diameter | Ukunyamezela (mm) |

| ngaphezulu kwe-0.80mm ukuya kunye nokubandakanya.1.60mm | +/-0.03 |

| ngaphezulu kwe-1.60mm ukuya kuthi ga kunye nokubandakanya.2.50mm | +/-0.03 |

| ngaphezulu kwe-2.50mm ukuya kuthi ga kunye nokubandakanya.4.00mm | +/-0.03 |

| ngaphezulu kwe-4.00mm ukuya kuthi ga kunye nokubandakanya.6.00mm | +/-0.04 |

| ngaphezulu kwe-6.00mm ukuya kuthi ga kunye nokubandakanya.8.00mm | +/-0.04 |

Ucingo olunzima oluGalisiweyo lwenziwa ukuze luhambelane nolu nyamezelo lwedayamitha lulandelayo:

| I-Nominal Wire Diameter | Ukunyamezela (mm) |

| ngaphezulu kwe-0.80mm ukuya kunye nokubandakanya.1.60mm | +/-0.04 |

| ngaphezulu kwe-1.60mm ukuya kuthi ga kunye nokubandakanya.2.50mm | +/-0.04 |

| ngaphezulu kwe-2.50mm ukuya kuthi ga kunye nokubandakanya.4.00mm | +/-0.04 |

| ngaphezulu kwe-4.00mm ukuya kuthi ga kunye nokubandakanya.5.00mm | +/-0.05 |

| ngaphezulu kwe-5.00mm ukuya kuthi ga kunye nokubandakanya.6.00mm | +/-0.05 |

| ngaphezulu kwe-6.00mm ukuya kuthi ga kunye nokubandakanya.8.00mm | +/-0.05 |

Amandla Okuqina (Mpa)

Amandla e-tensile achazwa njengowona mthwalo uphezulu ophunyeziweyo kuvavanyo lwe-tensile, ulwahlulwe ngummandla onqamlezileyo wesiqwenga sovavanyo locingo.Ucingo oluGalisiweyo luveliswa kusetyenziswa iingcingo ezithambileyo, eziphakathi neziqinileyo.Le theyibhile ilandelayo ichaza uluhlu lwe-tensile ngokwebakala:

| IBanga | Amandla Okuqina (Mpa) |

| IGalvanized – Umgangatho oSoft | 380/550 |

| Iigalvanized – uMgangatho oPhakathi | 500/625 |

| Iigalvanized - Umgangatho onzima | 625/850 |

Nceda uqaphele ukuba ubukhulu obukhankanywe ngasentla bubonisa kuphela kwaye ungakhankanyi uluhlu lobungakanani obukhoyo kuluhlu lweemveliso zam.

Ikhemistri yentsimbi

Ukudityaniswa kwamabakala entsimbi kusetyenziswa kunye neenkqubo zonyango lobushushu ukwenza amabakala athambileyo, aphakathi kunye nobunzima.Itheyibhile engezantsi ibonisa kuphela iikhemistri zetsimbi ezisetyenzisiweyo.

| IBanga le-Tensile | % Ikhabhoni | % Phosphorus | % IManganese | % Isilicon | % Isulfure |

| Ithambile | 0.05 ubuninzi | 0.03 ubuninzi | 0.05 ubuninzi | 0.12-0.18 | 0.03 ubuninzi |

| Phakathi | 0.15-0.19 | 0.03 ubuninzi | 0.70-0.90 | 0.14-0.24 | 0.03 ubuninzi |

| Kunzima | 0.04-0.07 | 0.03 ubuninzi | 0.40-0.60 | 0.12-0.22 | 0.03 ubuninzi |

Enye inzuzo yeucingo lwediphu eshushungamandla alo.Ukongezwa kwezinye isinyithi kwi-zinc kuphucula ukuqina kwayo kunye namandla okuqina, okwenza ukuba ifaneleke kwizicelo ezifuna imathiriyeli eyomeleleyo.La mandla akwenza kube luncedo ekudaleni amacandelo kwimizi-mveliso yeemoto kunye neyokwakha.Iyakwazi ukumelana nemithwalo enzima kwaye iyamelana ne-corrosion, iyenza ibe yinto efanelekileyo yokusetyenziswa kwangaphandle.

Enye inzuzo yeucingo lwediphu eshushungamandla alo.Ukongezwa kwezinye isinyithi kwi-zinc kuphucula ukuqina kwayo kunye namandla okuqina, okwenza ukuba ifaneleke kwizicelo ezifuna imathiriyeli eyomeleleyo.La mandla akwenza kube luncedo ekudaleni amacandelo kwimizi-mveliso yeemoto kunye neyokwakha.Iyakwazi ukumelana nemithwalo enzima kwaye iyamelana ne-corrosion, iyenza ibe yinto efanelekileyo yokusetyenziswa kwangaphandle.

I-Zinc alloy wire ikwangumqhubi obalaseleyo wombane.Le propati iyenza ilungele ukusetyenziswa kwizicelo zombane neze-elektroniki.I-alloy ingasetyenziselwa ukudala iingcingo zombane, izixhumi, kunye nezinye izinto ezifuna umgangatho ophezulu wokuqhuba.Ukongezwa kwezinye izinyithi kwi-zinc kukwaphucula ukuguquguquka kwayo kwe-thermal, iyenze ilungele ukusetyenziswa kutshintshiselwano lobushushu kunye nezinye izicelo ezifuna ukuhanjiswa kobushushu okusebenzayo.

Ukongeza kwiipropathi zayo zokusebenza, ucingo olushushu oluditshiweyo lwentsimbi luyinto eyaziwayo ngeenjongo zokuhombisa.Ukonakala kwayo kunye nokomelela kwayo kuyenza ilungele ukwenza iziqwenga zokuhombisa, ezinje ngeefreyimu zemifanekiso, iziphatho zamakhandlela, kunye nezinye izinto zokuhombisa ikhaya.I-alloy inokuthi igqitywe ngeentsimbi ezahlukeneyo, njengegolide okanye isilivere, ukuyinika inkangeleko ethe kratya.

Ngokubanzi, i-zinc alloy wire yimpahla eguquguqukayo eneempawu ezininzi ezizodwa ezenza ukuba zilungele uluhlu olubanzi lwezicelo.Ukonakala kwayo, amandla, kunye nokusebenza kwayo kuyenza ibe yintandokazi phakathi kwabayili, iinjineli kunye nabavelisi.Nokuba isetyenziselwa ukwakhiwa, ukwenza ubucwebe, okanye iinjongo zokuhombisa, ucingo lwe-zinc alloy luyinto enika ukuqina, ukusebenza, kunye nesibheno sobuhle.

I-Hot Dipped ngocingo lwentsimbi lwentsimbi

I-Galvanized Wire yenziwe kwi-AS / NZS 4534 "I-Zinc kunye ne-zinc / i-aluminium-alloy Coatings kwi-Steel Wire";I-BS EN 10244. Iingubo zensimbi ze-zinc ezisetyenziswe yinkqubo ye-galvanizing yindlela esebenzayo yokulwa ne-corrosion kwintsimbi.Ucingo lwegalvanized ngenjongo yokuvelisa ngokubanzi luyafumaneka kwi-standard galvanized coating okanye i-galvanized coating enzima.Iibhati ezisemgangathweni zigudileyo, nangona kunjalo ziyakwazi ukumelana nomhlwa kuneentsimbi ezinzima kwaye zihlala zisetyenziswa kwizicelo eziqhelekileyo zocingo.Abanye abasebenzisi bokugqibela abaqhelekileyo babandakanya iikheji, izibambo zebhakethi, izixhoma zeedyasi kunye neengobozi.Iingubo ezinzima zegalvanized zisetyenziswa kwiimeko apho i-atmospheric corrosion inzima.Abasebenzisi bokugqibela baquka iingcingo zenkxaso yezityalo apho kusetyenziswa imichiza, ukubiyela ipool okanye ichain mesh kwiindawo eziselunxwemeni.